I have been going back and forth over the past month working out some kinks in manufacturing, I thought I would share the experience here.

After the first round of samples, I noticed the nylon parts were displaying quite a bit of warping along their length as can be seen in the picture below. This isn't a major functional problem, but aesthetically I didn't like it when I closed the jaws together and they weren't quite flush, they basically looked like () or )( no matter what I did.

The reason for this is that the parts were too thick (exactly .25") and cooled unevenly after being molded. The golden rule of molded part design is keep wall thickness consistent and don't go above about 1/8" thick for most plastics. So why did I design the jaws to be so thick? Well I originally designed these parts to be machined, and when I ordered them I did a poor job of conveying that intent to the manufacturer. I sent a drawing, a CAD file and specified a finish, but never actually specified that the parts should be machined. Of course the manufacturer assumed for a plastic part I must want it molded. Next thing I know, I have beautiful molded nylon parts along with a nice little warping issue.

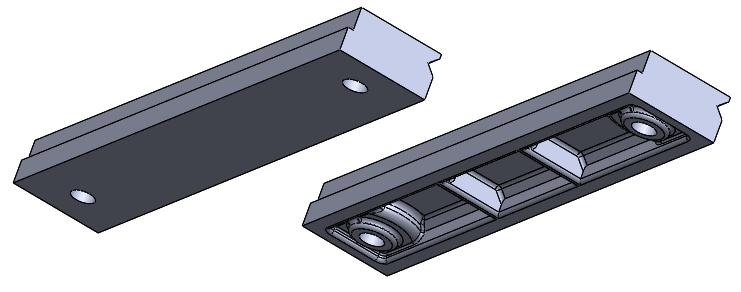

The manufacturer agreed to modify part of the mold, adding a hollow core to the parts as shown below (before and after).

No comments:

Post a Comment